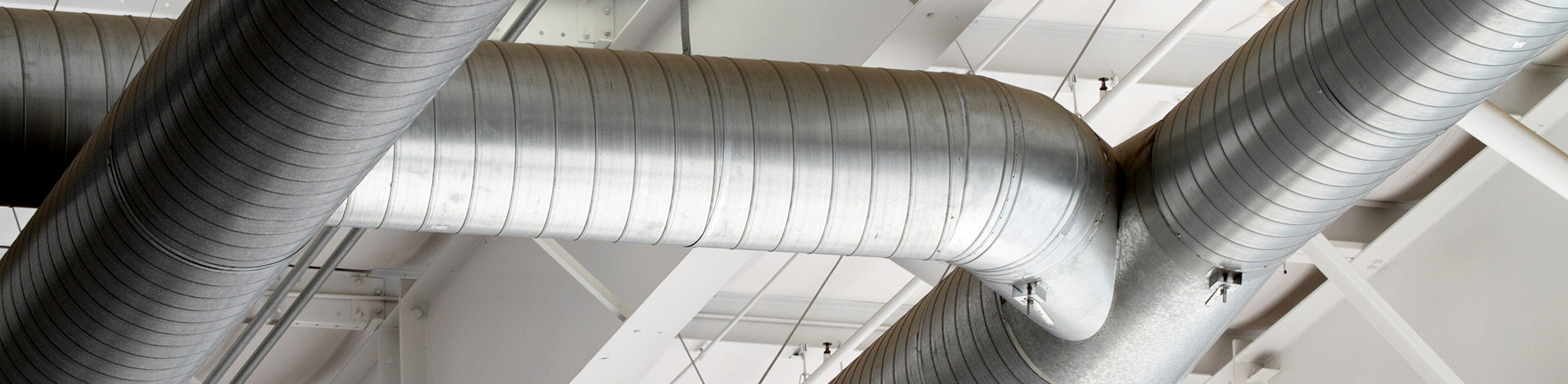

Five Essential Tips to Successfully Install Exposed Ductwork

Precision is paramount when carrying out exposed ductwork installations. Any mistake during the process can ruin the whole project. Luckily, you can achieve 100% customer satisfaction with the following exposed ductwork installation tips:

Confirm the Design

Sometimes a client may not have a specific design in mind and might ask you only to make the installation look good. It may take time to figure out a perfect plan for your client. However, you can identify what the client wants by showing them photos of previous projects.

The client may choose a minimum gauge to prevent dents and dings or go for a standard gauge. Whatever design you have in mind, make sure you consult the client before you begin the installation.

Identify Features

The features of your ductwork can influence its appearance. It’s essential to insist on the use of products with specific features or from particular manufacturers. For example, to create better-looking products, some manufacturers may decide to design oval, round or rectangular ducts. Ensure you inform your client about the features of the ductwork you intend to install.

Specify the Costs

An exposed duct system may cost slightly higher than a closed duct setup. However, the shipping methods and other services to keep the duct system in top shape can cost you more. If you want to save money, it’s essential to monitor your expenditure.

One of the best ways to cut down on cost is to ensure you pick a team that understands what the job entails, then set the requirements and trust their judgment. This way, you’ll be able to hold them responsible for designing and developing a setup that meets your clients’ needs.

Always note that a poorly functioning duct system may cost you more than expected. Therefore, you need to stay away from substandard designers, installers, and fabricators who offer lower prices but cannot meet the set requirements.

Function Definition

You need to ensure that the ductwork functions appropriately as per the construction standards. The first step is to confirm whether the duct system is sealed. The ASHRAE standard 90.1 recommends that all plenums and ductwork be developed to seal Class A. Remember that the purpose of ductwork is not to fill air into the box but to place the air to provide maximum comfort for the occupants.

Job Description

You need to ensure that every team member understands what the project entails. When everyone is on the same page from start to finish, you’ll have a duct system that’s well exposed.

For example, if you have to get new workers to help the installers offload the truck, ensure you inform them that the materials are meant for an exposed duct system. This way, the workers will carefully unload the truck without denting your ductwork.

Contact M & M Manufacturing for Quality Ductwork

Are you seeking a reliable metal sheet products manufacturer to meet your air distribution and ventilation requirements? At M&M Manufacturing, we provide a wide selection of ductwork, accessories, and fittings to make your construction project a success. Contact us online or call us at 817-336-2311 to learn more about our services and get an estimate.